Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes XLPE (Cross-liked Polyethylene)

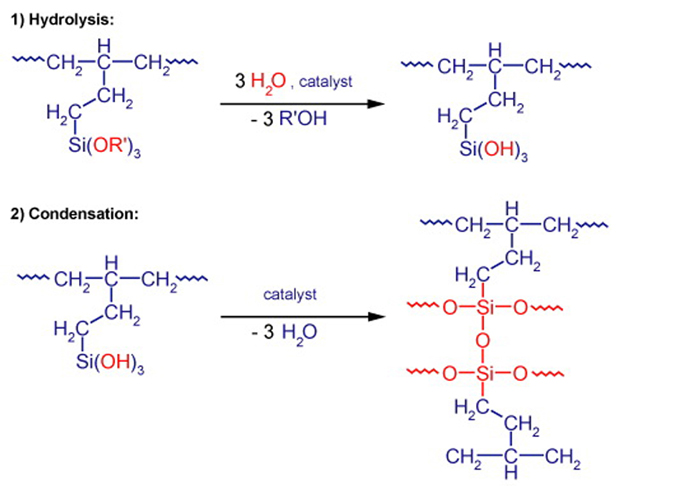

XLPE (Cross-liked Polyethylene) Silaine Crosslinking Mechanism

Silaine Crosslinking Mechanism صفحه Silaine Crosslinking Mechanism

Silaine Crosslinking Mechanism

Why Use Silaine Crosslinking Technology?

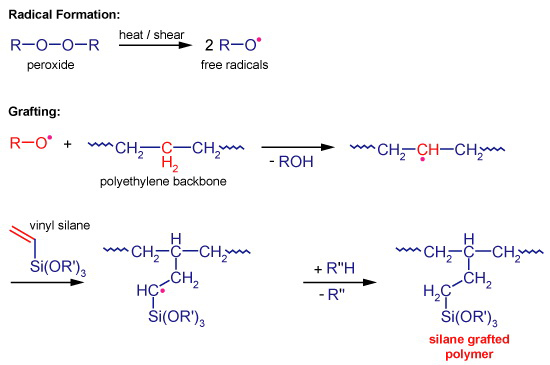

For high performance polyethylene applications, requiring higher temperature, creep, abrasion and chemical resistances, crosslinking is a must. Of all the crosslinking technologies, Silaine is the one which exhibits the greatest process flexibility (by providing the possibility to trigger the crosslinking after extrusion) and superior mechanical performance. As opposed to other processes, Silaine Crosslinking technology is easy to implement and does not require special processing equipment.

Silaine Crosslinked PE is called PEX or XLPE .

Silaine technology consists of two steps:

• Step 1: incorporation of the Silaine into the polymer, either by grafting of vinylsilane onto the polymer ackbone or by copolymerization of vinylsilane with ethylene in the polymerization reactor, and

• Step 2: crosslinking in the presence of water, generally catalyzed by tin compounds or other suitable catalysts. This second step can be controlled and made during or after the extrusion process. This is the difference between a One-Step and a Two-Step Process.